Products List

Contact Us/ Contact Us

Address:Three Hekou Industrial Zone, Zhenglu Town, Changzhou

Contacter:Mr Fang

Phone:1350614400976

Tel:0519-88909038

Fax:0519-88909038

Website:www.ielixmu.org

Email:fangqun1968@163.com

Zip code:213115

Product

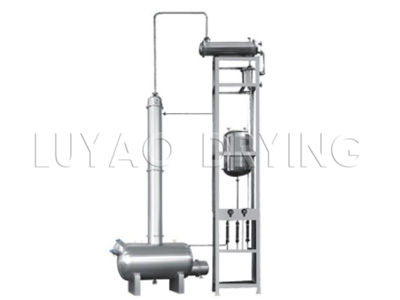

Alcohol recovery tower

Detailed Description

Equipment structural characteristics and technical performance

??

The device uses highly efficient ceramic corrugated packing. The

distillation column body is made of stainless steel, thus preventing the

iron filings from clogging the filler and prolonging the service life

of the device. All parts of the device that come into contact with

alcohol, such as condensers, surge tanks, and cooling coils, are made of

stainless steel to ensure that the finished alcohol is not

contaminated. The W-type distillation pot adopts a detachable U-shaped

heating pipe. During the inspection, the U-shaped heating pipe can be

removed from the kettle to facilitate the cleaning of the outer wall of

the heating pipe and the inner wall of the distillation pot.

??

The ZW type eliminates the need for an indirect heating still. Condenser

tube heat exchanger, but also according to user requirements to supply

spiral plate heat exchanger, cooler coil cooler, using coil cooler and

matching supply tank and specific gravity measuring device.

Product Usage

??

The device is applicable to the dilute alcohol recovery in

pharmaceutical, food, light industry, chemical industry and other

industries. Also suitable for the distillation of other solvents such as

methanol. According to the user's requirements, this device can dilute

about 30° of dilute alcohol to 90-95° alcohol. If the finished product

requires a high degree of alcohol, the reflux ratio can be increased,

but the production is reduced accordingly. ??There are five types

of

W-type device composition , each type includes the

corresponding configuration of the distillation tower, distillation

kettle, condenser, cooler, regulator tank, specific gravity measuring

device. Among them, the W-200 and W-300 distillation towers are

installed directly on the distillation still. The W-400, W-500, and

W-600 distillation columns were installed separately from the

distillation stills.

??

ZW-type ZW-200, ZW-300 two specifications, each specification includes

the corresponding supporting preheater, distillation tower, condenser,

cooler, regulator tank, specific gravity measuring device.

??

Other auxiliary equipment and instruments such as: metering tanks,

storage tanks, transfer pumps, rotameters, temperature indicating

instruments and other user-owned, our factory can also be processed

according to user requirements or on behalf of the order supply.

Technical parameters

◎ feed concentration: 30% to 80%

◎ discharge concentration: 90% to 95%

◎ reflux ratio: R = 13 (according to the inlet and outlet material concentration )

◎ residue discharge alcohol concentration: W type ≤ 3% , ZW ≤ 1%

◎Production capacity (kg/h): See the table on the right

| model | Tower diameter (mm) | 30% to 40% feed capacity | 60%-80% feed capacity | ||

| 90% | 95% | 90% | 95% | ||

| W-200 | Φ200 | 35 | 26 | 45 | 36 |

| W-300 | Φ300 | 80 | 61 | 100 | 80 |

| W-400 | Φ400 | 150 | 120 | 180 | 140 |

| W-500 | Φ500 | 230 | 185 | 275 | 220 |

| W-600 | Φ600 | 335 | 270 | 400 | 320 |

| ZW-200 | Φ200 | 95 | 60 | 110 | 80 |

| ZW-300 | Φ300 | 200 | 120 | 240 | 165 |